Supply Chain Technology

Following pandemic-related disruptions, supply chains are in a state of transition. To avoid future backlogs and disruptions, many solutions are being explored including a switch from just-in-time inventory to just-in-case, as well as near-shoring and on-shoring. Technology can play a significant role in securing global supply chains via automation, software, and connectivity. New technology developments can be utilized from production to storage, delivery, and recycling.

One of the more interesting observations about the COVID-19 pandemic era was the way in which it expanded words and phrases used in general conversation. Prior to the pandemic, it was unlikely that people routinely talked about the effectiveness of mRNA vaccines or how long a virus could stay viable on a shopping bag. And conversations about the daily trip to the supermarket suddenly incorporated phrases like “supply chain disruptions.”

We started writing about supply chains back in December 2021 in our report Global Supply Chains: The Complicated Road Back to Normal. At the time, global markets were unbalanced. There was strong demand for goods, as many who were sitting home due to lockdowns or remote work were clicking on “Add to Cart.” On the supply side, border closings and lockdowns kept production sites shuttered. At the time, we noted that because there was more than one cause or event that had gotten us into that situation, one single solution would not relieve the stress.

Then came the armed conflict between Russia and Ukraine, which added a new layer of supply chain pressure and new challenges for the global economy. Together with the issues from the pandemic, the supply chain management practices that prevailed in the years before the pandemic were questioned, especially whether global supply chain structures were robust, cost-effective, and reliable, and whether the demand for goods was relatively smooth and predictable.

With vulnerabilities in supply chains exposed, we noted that many firms would feel the need to take the lessons from supply chain disruptions on board and adjust their operations. One of our suggestions was to embrace digitalization and technology more broadly throughout the supply chain.

Although technology had been slowly added over the year into the production and distribution areas of the economy, we believe the recent supply chain disruptions are proving to be a catalyst for technology adoption.

From robotics in manufacturing and automated guided vehicles in warehouses, new technologies in the production area of the economy can help to automate processes, increase productivity, and lower costs. In the delivery sector, technology can help decrease delivery times and novel transportation solutions can lower delivery costs. New technology such as artificial intelligence and machine learning can help companies bring products to market faster and more efficiently. Finally, digitization and documentation can help keep supply chains running smoothly.

In our full report, we look at 20 different areas of supply chain technology that could help companies enhance their supply chain management practices. Some are technologies that are already used in practice, while others are more conceptual. All are likely to help lead to a more stable global supply chain.

Hopefully supply chain technology can ensure that future conversations about the trip to the market will center around what’s for dinner instead of what’s missing on the shelves.

Production and Storage

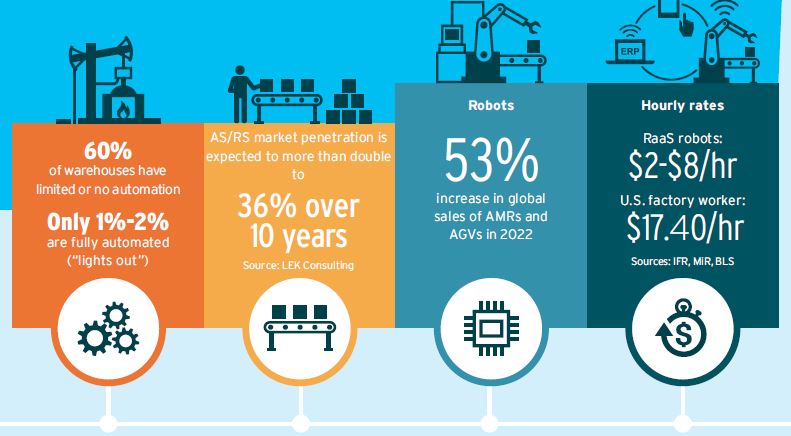

While humans still perform 72% of manufacturing tasks, the use of robots is on the rise, including Automated Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs). Lower costs and higher speeds can be achieved through technologies such as Robots-as-a-Service (RaaS) subscriptions and 3D printing. While warehouses are still largely manual, the use of Automation Storage and Retrieval Systems (AS/RS) is growing.

Delivery and Recycling

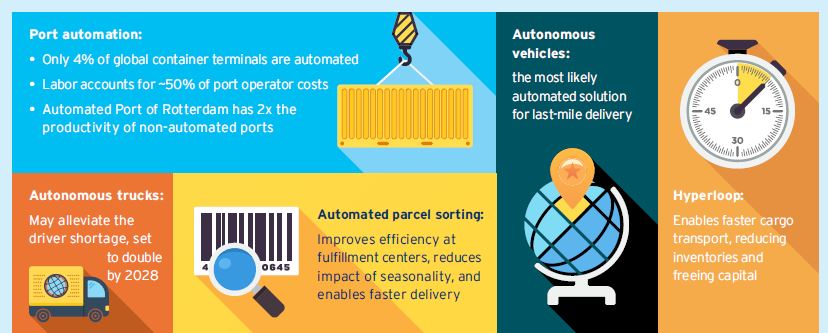

Globally, automation at container terminals remains low despite evidence it increases throughput and reliability while reducing costs. Other technologies such as autonomous trucks, hyperloop transport, automated parcel sorting, and automated last-mile delivery technologies can produce further efficiencies in logistics.

Decision Making

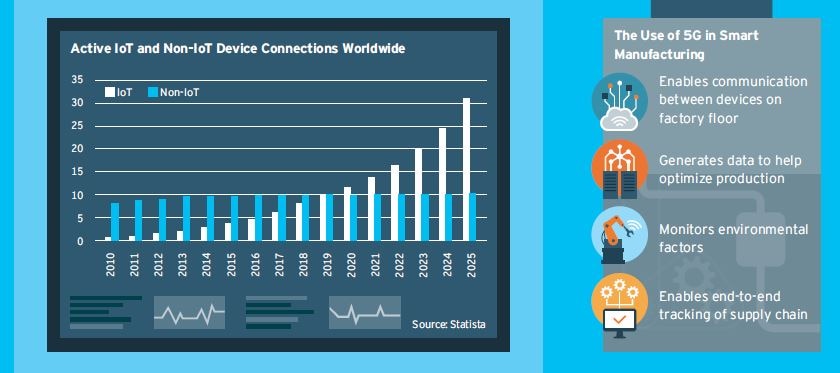

The Internet of Things (IoT) is providing greater visibility over supply chains and enables better decision making through artificial intelligence (AI) tools. Greater connectivity from 5G enhances these capabilities, with quantum computing expected to further optimize supply chains. As sensor costs fall, the number of IoT-connected devices is expected to rise significantly.

Digitization and Documentation

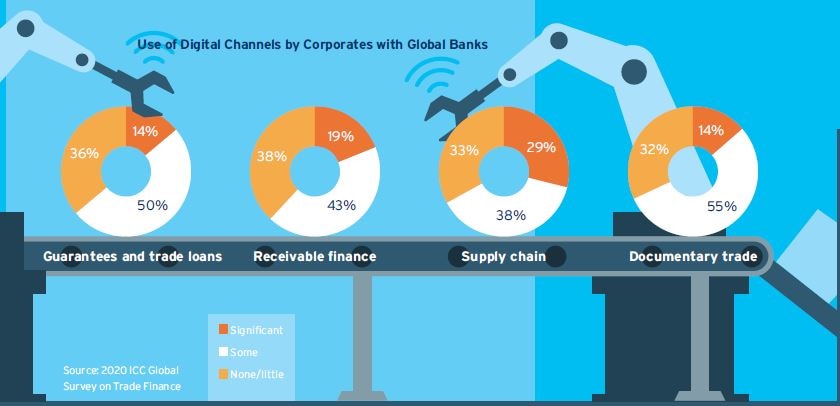

Less than 10% of trade documents are fully digitized, but this is changing with the Digital Documentation Initiative (dDOC). Interoperable Digital ID systems and digital payments (including blockchain and tokenization) in the supply chain may bring further change, helping to improve supply chain resilience and increasing transparency to stakeholders.